How to Choose the Right PVC Fittings for Your Plumbing Projects in 2025

When embarking on plumbing projects, the choice of materials can significantly impact both the efficiency and durability of the installation. Among these materials, PVC fittings have gained immense popularity due to their versatility, cost-effectiveness, and ease of installation. As we look ahead to 2025, understanding how to select the right PVC fittings becomes crucial for homeowners and professionals alike. Given the ever-evolving landscape of plumbing solutions, it's essential to be informed about the various options and best practices when working with these fittings.

In this guide, we will explore the fundamental aspects that should influence your decision-making process regarding PVC fittings for your plumbing projects. From understanding the differences in various types of fittings to considering factors such as pipe compatibility, pressure ratings, and environmental impact, the goal is to equip you with the knowledge necessary to make informed choices. This introduction sets the stage for making effective decisions that ensure your plumbing system not only functions well but also stands the test of time. Join us as we delve deeper into the world of PVC fittings and how they can be the backbone of your plumbing success in 2025.

Understanding the Basics of PVC Fittings for Plumbing Use

When embarking on plumbing projects, understanding the basics of PVC fittings is essential for effective installation and long-term functionality. PVC, or polyvinyl chloride, is a popular choice for plumbing due to its durability, resistance to corrosion, and ease of handling. The fittings, which come in various shapes and sizes, play a critical role in connecting pipes and directing the flow of water through a plumbing system. Common types include elbows, tees, and couplings, each designed for specific junctions or angles in the piping layout.

Choosing the right PVC fittings begins with assessing the specific requirements of your plumbing project. Consider the diameter of the pipes being used and the pressure ratings needed based on the intended use. It's crucial to ensure compatibility between fittings and pipes to prevent leaks or structural failures. Additionally, understanding the various types of connections—such as solvent weld and threaded—can affect both assembly and future maintenance. By grasping these fundamentals, you can make informed decisions that will lead to successful and efficient plumbing installations.

Identifying Different Types of PVC Fittings Available in 2025

When considering plumbing projects in 2025, understanding the variety of PVC fittings available is crucial for making informed decisions. PVC fittings are categorized into several types, each designed for specific applications. The most common types include elbows, tees, and couplings, which offer flexibility in pipe alignment and connections. According to a recent industry report from the Plastic Pipe and Fittings Association, the demand for rigid PVC fittings is expected to grow by approximately 4.2% annually through 2025, driven by increased construction activities and renovation projects.

In addition to standard fittings, specialized PVC fittings such as cross fittings and bushings are also gaining popularity. These fittings allow for more complex plumbing arrangements and can help optimize space and material use in plumbing systems. Furthermore, advancements in manufacturing technology have led to the development of lead-free and environmentally-friendly PVC options, catering to changing consumer preferences and regulatory standards. As detailed in the latest market analysis, the shift towards sustainable plumbing solutions is prompting increased innovation in product design and material sourcing, and these trends will shape the PVC fitting market in the coming years.

Evaluating Quality and Durability of PVC Fittings for Projects

When it comes to selecting PVC fittings for your plumbing projects, evaluating the quality and durability of the materials is paramount. According to a report by the Plastic Pipe and Fittings Association (PPFA), high-quality PVC fittings can last more than 50 years when properly installed, making it essential to avoid lower-grade options that may lead to premature failure. The typical strength and chemical resistance of PVC materials stem from the manufacturing processes and the purity of the raw materials used. Ensuring that the products meet relevant ASTM (American Society for Testing and Materials) standards can help in identifying reliable fittings that can withstand the rigors of plumbing applications.

Furthermore, 2023 industry trends indicate a growing focus on sustainability and eco-friendly practices in the production of PVC fittings. As part of this movement, manufacturers are increasingly adopting recycled materials and innovative techniques that enhance the durability of their products while minimizing environmental impact. A study conducted by the Sustainable Sources Initiative suggests that fittings made from advanced formulations not only decrease the likelihood of leaks and cracks but also offer improved resistance to adverse conditions like UV exposure and extreme temperatures. Consequently, plumbing professionals and DIY enthusiasts alike should prioritize fittings that are not only high in quality but also developed with sustainability in mind, ensuring both short-term efficacy and long-term performance.

Quality and Durability of PVC Fittings for Plumbing Projects in 2025

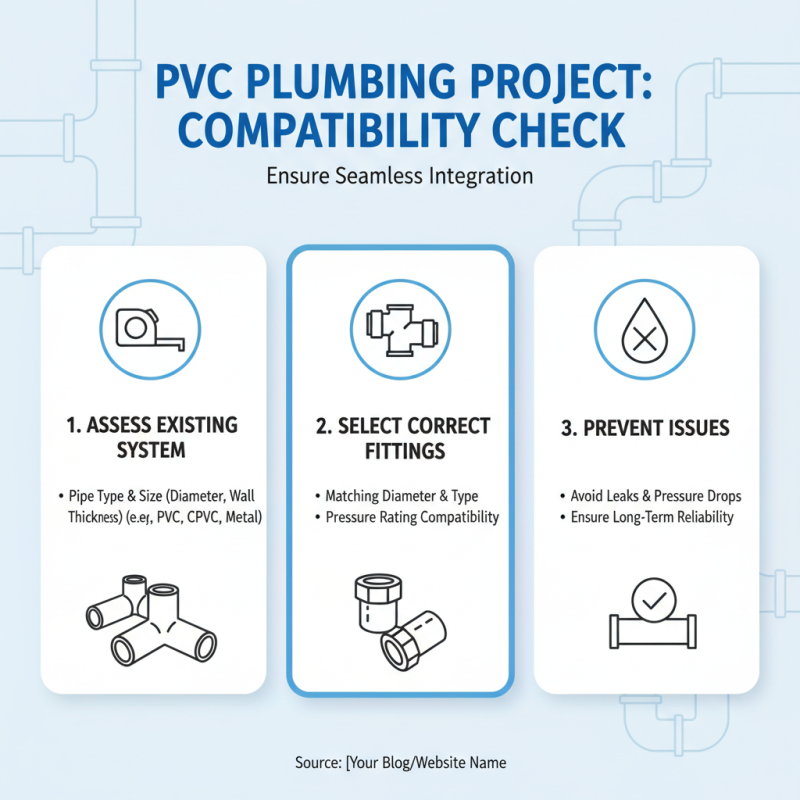

Assessing Compatibility with Existing Plumbing Systems

When planning plumbing projects using PVC fittings, one crucial aspect to consider is compatibility with your existing plumbing systems. Ensuring that new PVC parts will integrate seamlessly with the current layout can prevent issues such as leaks or pressure inconsistencies. Begin by checking the type and size of your existing pipes, focusing on diameter and wall thickness. This knowledge will guide you in selecting the correct fittings that match not only in size but also in the pressure ratings suitable for your system.

Tips for assessing compatibility include measuring your existing plumbing accurately and consulting compatibility charts for various fittings. Additionally, consider the intended use of the plumbing system; for instance, drainage systems may require different pressure handling compared to potable water systems. Engage with local plumbing codes to ensure your selections meet legal requirements as well.

Another essential tip is to evaluate the materials of your existing fittings. Some older systems may use metal or other types of plastic, which can react poorly with PVC. In such cases, coupling adapters or transition fittings may be required. By taking the time to assess these factors, you can confidently choose the right PVC fittings that enhance your plumbing projects, ensuring longevity and reliability in your installations.

Considering Cost-Effectiveness and Availability in the Market

When choosing PVC fittings for your plumbing projects in 2025, cost-effectiveness and availability in the market are critical factors to consider. PVC fittings are known for their affordability compared to other materials, which makes them a popular choice for both DIY homeowners and professional plumbers. As you plan your project, it’s essential to compare prices from multiple suppliers to ensure you get the best deals without sacrificing quality. The rise of online marketplaces has made it easier to find competitive pricing; however, it’s important to verify the reliability of the seller before making a purchase.

Availability is another crucial aspect to keep in mind. In recent years, supply chain issues have sometimes caused delays and shortages in plumbing supplies. To avoid potential setbacks in your project timeline, consider sourcing your PVC fittings from local suppliers who can offer immediate stock. Additionally, keeping an eye on market trends can help you anticipate which products might be in higher demand, allowing you to purchase in advance to mitigate any future availability issues. Balancing these considerations will not only save money but also ensure your plumbing project proceeds smoothly.

Related Posts

-

What is PVC Pipe Fittings and Their Importance in Plumbing Solutions for Efficient Water Management

-

2025 Top PVC Pipe Fittings: Essential Guide for Quality Plumbing Solutions

-

Top 10 Plastic Water Troughs: Expert Reviews and Insights on Durability and Capacity for Optimal Livestock Management

-

Understanding the Importance of Water Storage for Sustainable Living Solutions

-

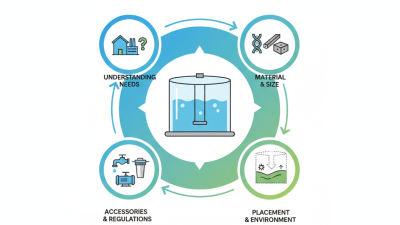

How to Choose the Right Large Water Tank for Your Needs: A Complete Guide

-

How to Choose the Right Water Storage Tanks for Your Needs